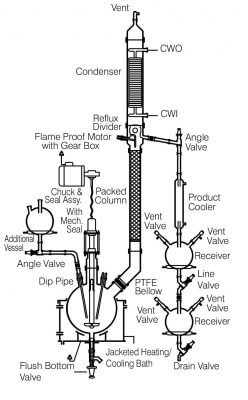

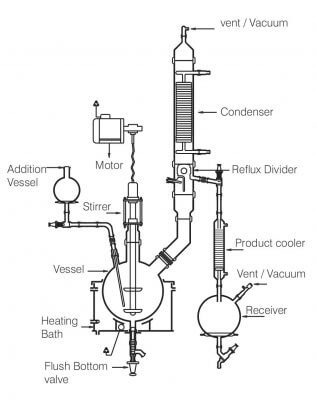

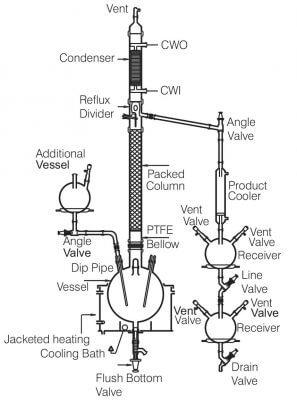

The unit has been designed to suit the customer’s requirement of a combination of versatile reaction/distillation or combination for pilot plant work.

This has a flexibility of working at atmospheric pressure as well as under vacuum.

The typical unit has a reaction vessel fitted with a metal heating/cooling bath having a facility for heating and cooling bath by means of heating/cooling Fluids as a media.

The Standard system is equipped with stirrer heaving mechanical seal, a packed column on the side neck of the vessel, reflux divider, coil type condenser and or receiver system having a product, cooler, vent, drain and vacuum valves, Option of speed variation by mechanical variator or electronic variator can be provided.

The receiver system is equipped with product cooler. Vent/vacuum valve and drain valve.

The above unit are available in 10 Ltr., 20 Ltr., 50Ltr.,100 Ltr., 200 Ltr. & 300Ltr capacity with a spherical reactor.

| Reactor Capacity | Bath KW | Addition Vessel | Vapour Line | Condenser HTA M 2 |

Cooler HTA M2 |

Receiver Size | Reference |

|---|---|---|---|---|---|---|---|

| 10 L | 2 | 2 L | 50 DN | 0.2 | 0.1 | 2L, 2L | SFFRU 10 |

| 20 L | 3 | 2 L | 80 DN | 0.35 | 0.1 | 2L, 5L | SFFRU 20 |

| 50 L | 4.5 | 5 L | 100 DN | 0.5 | 0.2 | 5L, 10L | SFFRU 50 |

| 100 L | 6 | 10 L | 150 DN | 1.5 | 0.35 | 10L, 20L | SFFRU 100 |

| 200 L | 9 | 20 L | 150 DN | 1.5 | 0.35 | 10L, 20L | SFFRU 200 |

| 300 L | 10.5 | 20 L | 225 DN | 2.5 | 0.5 | 20L, 20L | SFFRU 30 |

Optional Items

- Heating mantle instead of jacketed heating / cooling bath.

- Simple drain Valve instead of the flush bottom valve.

- MS PTFE lined stirrer instead of glass stirrer.

- Variable frequency drives for variable speed.

- Cylindrical vessel instead of the spherical vessel. TM

- SIGFOLDI-JACKET vessel instead of a spherical vessel without heating bath and heating mantle.

Reviews

There are no reviews yet.